SYSTEM

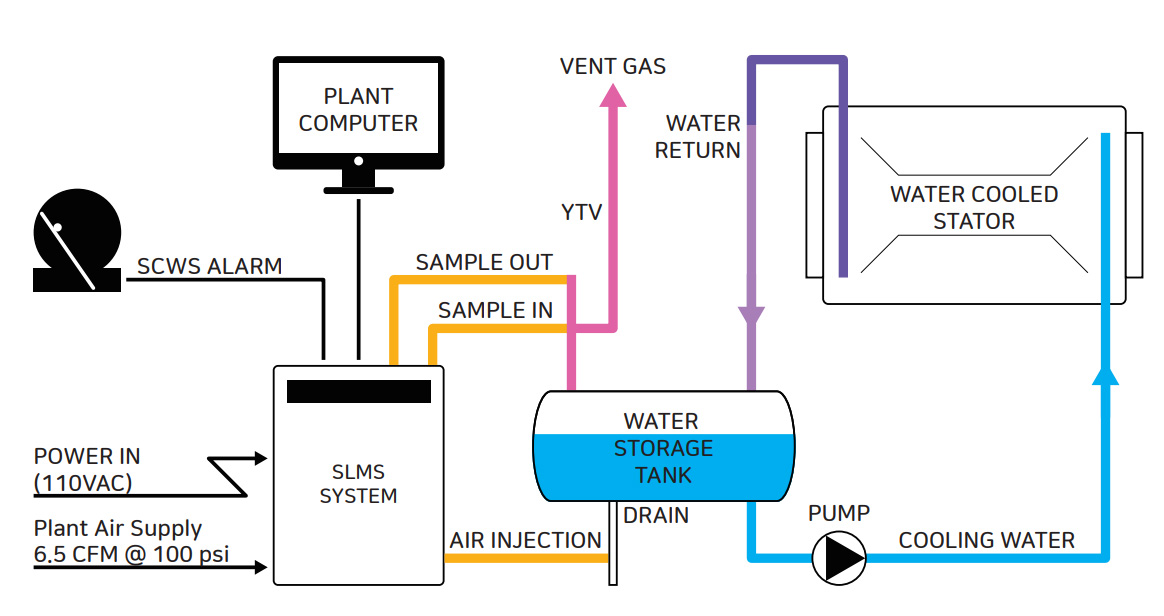

Stator Leak Monitoring System

- 발전기에서 수냉식 고정자 권선의 고정자 수냉각 시스템 속으로 누설되는 수소의 속도와 부피를 계산하고 기록

- 냉각수의 적절한 산소 수준 유지를 위해 처리된 공기를 지속적으로 공급

- 고정자 권선 절연 손상과 고정자 권선의 동 부식 방지

System Description

- 1 시료가스는 발전기 냉각수 tank의 vent 파이프로부터 공기를 sampling하여 실시간으로 측정

- 2 센서 오염을 최소화하기 위한 수분 제거 및 먼지 필터링센서 오염을 최소화하기 위한 수분 제거 및 먼지 필터링센서 오염을 최소화하기 위한 수분 제거 및 먼지 필터링센서 오염을 최소화하기 위한 수분 제거 및 먼지 필터링

- 3 ECD type 가스 디텍터 사용으로 고감도, 안정성이 좋음 (미세한 누설률 부터 측정가능, 온도변화에 강함)

- 4 저농도 수소 검출 센서를 이용하여 수소 0~10%Vol 을 측정하기 위한 가스희석장치 적용

- 5 보호 기능 (Flame Arrestor, Panel inside check, Water check in pipe, Self-check(flow, detector)

- 6 운용하기 편리한 HMI 구성

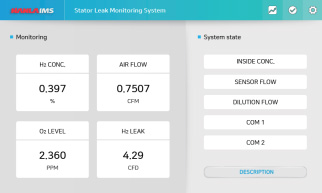

Operation Screen

- 7" Touch HMI

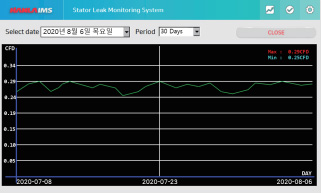

- 수소 농도, 수소 누설률, Air injection flow, 용존산소량 표시

- 알람, System 상태 등 각종 정보 표시

SPECIFICATIONS

| 구분 | 상세내용 |

|---|---|

| 동작 |

|

| 감도 |

|

| 정확도 |

|

| 표시 |

|

| 데이터 저장 |

|

| 통신 |

|

| O/A 치수 |

|

| 주변 온도 |

|

| 공기 공급 |

|

| 전원 |

|

| 공급 공기 품질 |

Air Treated by SLMS to Provide

|

| 센서 교정주기 / 교체주기 |

|

Headquarters and Factory

- A. 115, Hwajeonsandan 1-ro, Gangseo-gu, Busan

- T.+82-51-601-7000

- F.+82-51-831-1850

2nd factory

- A. 15, Hwajeonsandan 5-ro, Gangseo-gu, Busan

- T.+82-51-601-7000

- F.+82-51-831-1850

3rd factory

- A.63 Garisae 3-ro, Gangseo-gu, Busan

- T.+82-51-601-7000

- F.+82-51-831-1850

Ship Repair

- A.360-226, Indeok-ro, Shuangyang-eup, Gwangyang-si, Jeollanam-do

- T.+82-61-798-7690

- F.+82-61-798-7676

- E.shiprepair@hanlaims.com

Copyright (C) HANLA IMS co.ltd. All Rights Reserved.