SMART SYSTEM

VRCS

Valve Remote Control System

Valve Remote Control system manufactured by HANLA IMS ard designed according to

shipyard specification,client’s requirements and rule requirement of classification society.

Our system division in HANLA IMS make an effort to supply the best valve remote

control system at a resonable price.

Valve Remote Control System

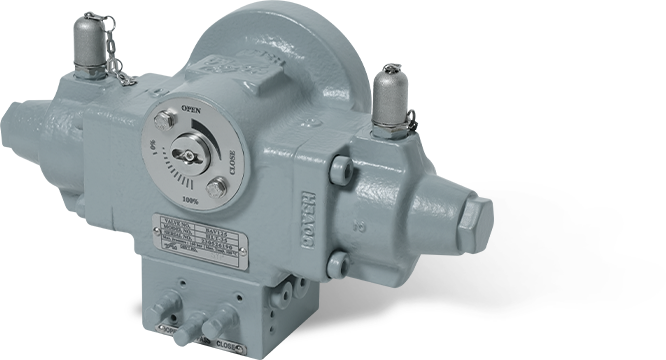

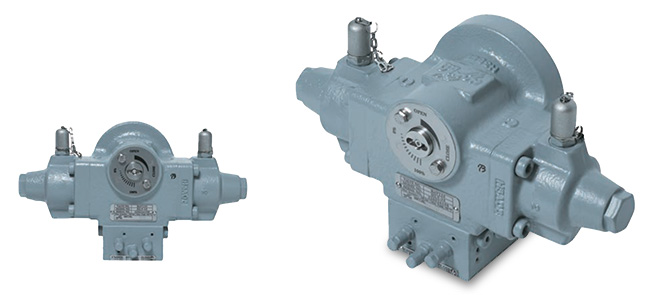

Hydraulic Actuator

HANLA IMS hydraulic actuators type HLT-series are especially designed for the operation of quarter turn valves such as butterfly valve, plug valve and ball valves. HLT-Series hydraulic actuators are available in a range of up to 12,800 N.m at maximum working pressure (16MPa - 160 bar).

HLT-Series hydraulic actuators can be operated by stationary hand pump, portable hand pump or manual hydraulic transmitter via quick connectors or fitted pipes.

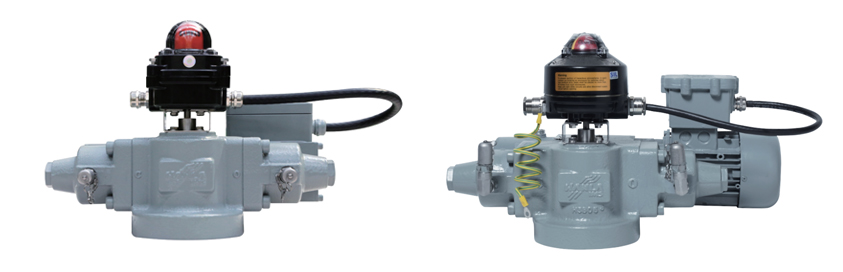

Electro Hydraulic Actuator

Electro-hydraulic actuator (EHLT-Series) consists of hydtaulic

actuator for operating valves, limit weitch box for receiving single

feedback, and micro power unit for supplying oil pressure.

Micro power unit consists of electric motor with junction box,

oil tank, and main block.

Main block consists of relief valve and pilot check valve. Hydraulic

pupm connects with main block at the inside of oil tank.

Normal and

ex-proof type are available for electric motor.

It is made of aluminum

body in addition to main block.

IP68 of Electro-hydraulic actuator is

available for double acting type.

Local Control Cabinet

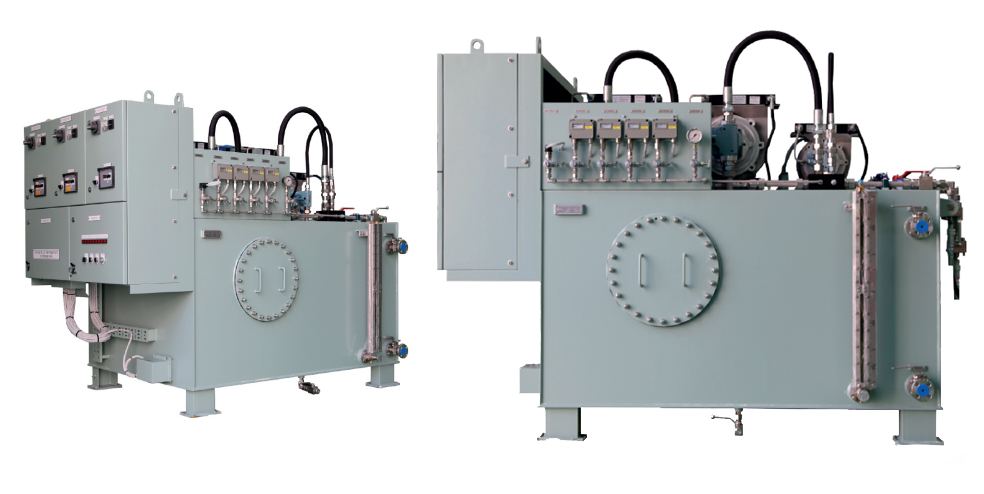

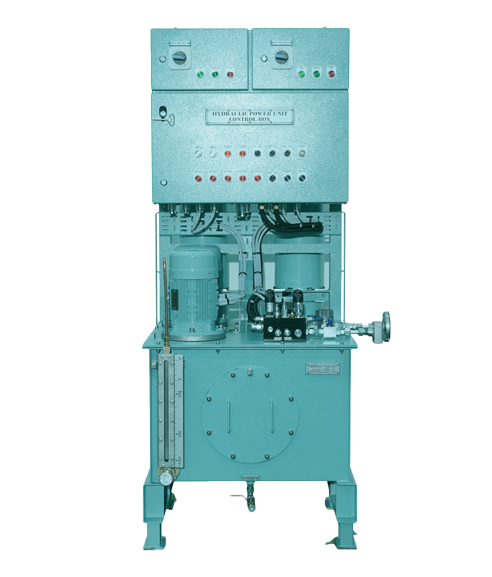

Hydraulic Power Unit

Hydraulic power unit is designed to simple arrangement, easy control and easy maintenance.

Control box of hydraulic power unit can control the hydraulic pumps (Main/Stand-by) and pump selection and monitor the abnormal alarm as like pressure, level and temperature.

In order to keep the adequate capacity of the accumulator, the hydraulic power delivers the higher pressure than the designed working pressure of VRC system.

But the working pressure of VRC system can be limited at the required working pressure by the faction of the pressure reducing valve.

Features

- Simple design & arrangement

- Easy control & operation

- Easy Maintenance

- Constant hydraulic pressure

Components

- Hydraulic pump

- Electric motor

- Accumulator

- Pressure relif valve

- Pressure switch for control with pressure gauge

- Pressure switch for alarm with pressure gauge & transmitter

- Pressure reducing valve

- Level indicator

- Level switch

- Filter & indicator

- Temperature switch

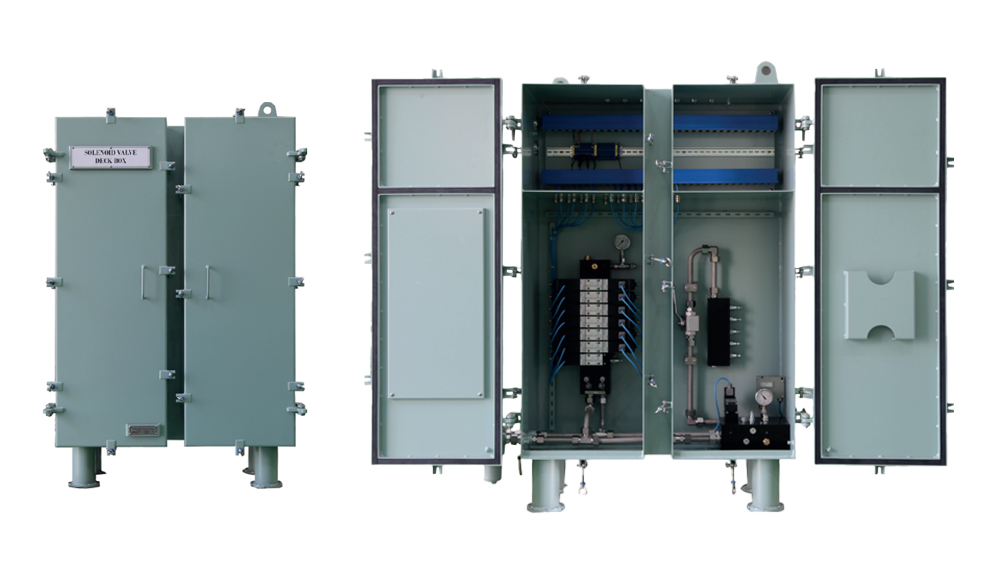

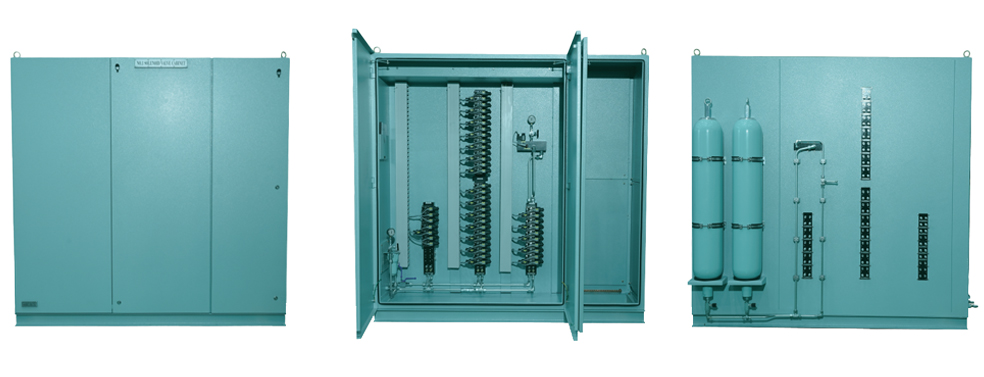

Solenoid Valve Cabinet

Solenoid valve cabinet is divided into the hydraulic part and the electric part.

The hydraulic part consists of solenoid valves, flow control valves, manifold blocks, pressure filter and feed back components etc.

The electric part arranges to connect for electric wiring of valve control and feed back signal.

Solenoid valve cabinet controls in accordance with the function of each valve and it is an equipment to process its signal.

Through this equipment, it sends the valve position signal to control console or computer and receives the valve position signal, and controls each valve.

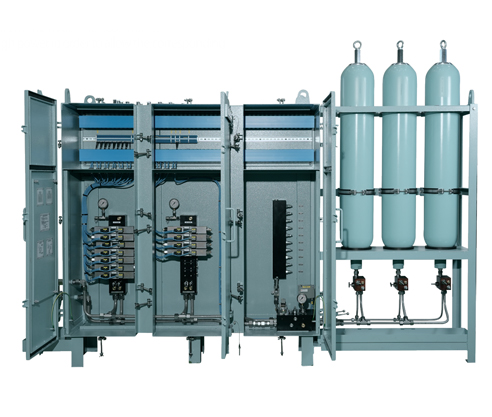

Dual Fuel System

Valve remote control system for LNG-DF consist of cargo valve control system and ballast valve control system.

Conponents

- Hydraulic pump

- Electric motor

- Pressure return filter

- Pressure transmitter

- Level switch & Level indicator

- Pressure relief valve

- Temperature switch

- Control panel for Hydraulic power unit

- Fitting, gauge and valve part

- Accumulator

Conponents

- Steel cabinet(IP44 grade)

- Solenoid valve (Non-Ex. type)

- Manifold block

- Pressure filter unit

- low control valve

- Pressure guage

- Stop valve

- ESD block with electric/hydraulic components

- Accumulators